CNC Router: Tips to Choosing a Machine for your Woodworking

Do you want a CNC Router? With an impressive bouquet of advantages such as low cost to design, accessibility, and reliable repeatability, to name a few, CNC machines have gained significant popularity in the last few years. However, this boom has introduced a whole lot of options in the market, which makes settling on a single machine tricky at best. Every CNC machine is fighting for the top spot and boasting of features one may not have even heard of! At the same time, the problem is aggravated by the fact that different individuals will have different requirements depending on the CNC machining process. So, to help you out, we have a guest post from an expert on the topic.

And so, if you are in the market for a CNC router machine for woodworking projects, we have compiled a list of some of the most important considerations to bear in mind as they help you in your quest. So, without any further ado, let’s check these out!

- Drive System

Providing automatic and precise motion control is one of the key functions of a CNC machine. And this is made possible through a drive system. Typically, these can be of three main types - Rack and Pinion, Lead Screw, and Ballscrew. The Ballscrew is the most expensive of the lot, but it also makes up for it by offering higher accuracy and the ability to hold a larger material size. On the other hand, Lead Screw and Rack, and Pinion would be cheaper alternatives and perform the task at hand, but the final product may not be as nice.

- Motor System

When it comes to the motor system driving the CNC machining process, buyers primarily have to choose between Stepper motors and Servo motors. Stepper motors are powered by pulses and do not receive location feedback under normal circumstances. In contrast, servo motors are under constant monitoring with facilities to correct position. Another differentiator is that servo motors are more suited for high-speed, high torque applications that require constant load change, which justifies their high cost.

- Spindle

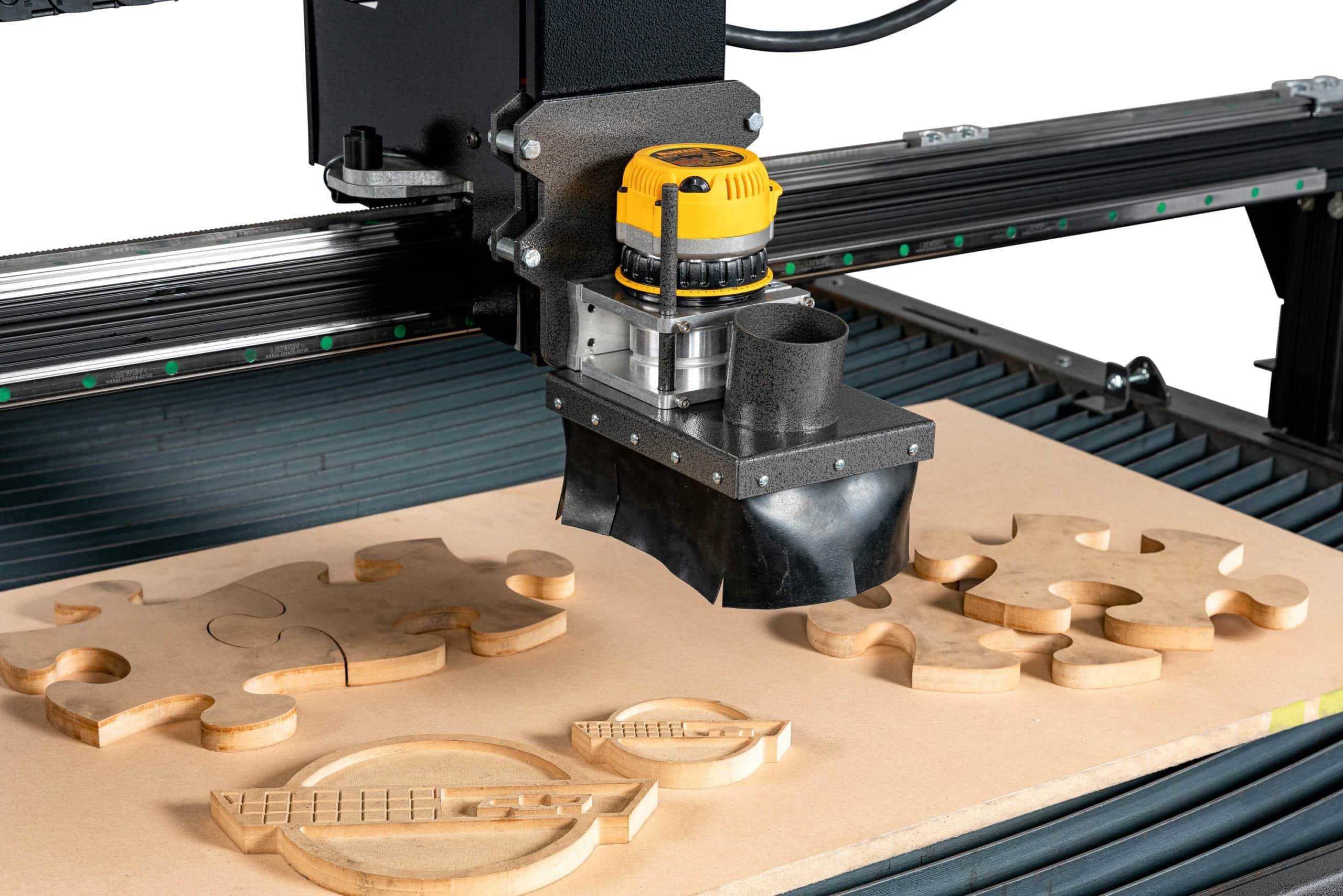

Spindles are essentially the motors that perform the actual CNC machining process using the appropriate tools. These come in various shapes and sizes and can perform a niche task or a variety of functions. As such, depending on your load and machining function, read up on the capabilities of the spindle, such as its torque, RPM, load rating, power requirement, spindle motor type, collet type, and size, etc.

- CNC Router Machine Weight

While machine weight may directly impact the portability of the machine, heavy CNC machines are an indication of robust construction. Additionally, it also corresponds to improved performance. But if the machine is supposed to move around a lot in the workshop, it would help if you invest in one that is more lightweight.

- Dust Collection

Considering that CNC woodworking machines will generate a lot of sawdust, chips, and shavings, it only makes sense to factor in the dust collection system. Look for one equipped with a vacuum system to clear up the atmosphere and general area of operation. Ensure that the dust collection system scales up with the refuse produced by the machine and is placed at a strategic location for maximum usability.

- Spare Part Availability

Nothing can be worse than witnessing a part of your CNC machine dying out, only to learn that a spare is no longer available in the market! And given that wear and tear and breakdowns are common occurrences, you need to ensure that the machine you choose can be repaired easily without worrying about the spare parts. This direct relation of spare part availability with machine life highlights its importance in minimizing downtime and machine out of use status.

- Feed Rate

The machine's feed rate indicates the speed at which the machine can process the job and produce the finished product. When paired with the spindle speed, this feed rate determines the health and performance of the tool. For instance, fast feed rate and slow spindle RPM can cause tool breakage. Conversely, slow feed and fast spindle rates can increase friction and reduce tool life. Plus, the feed rate is subject to change depending on the nature of the wood material that you may be working on.

- Cost

Eventually, every selection boils down to the budget and the corresponding cost of the machine. Given that prices can range from USD 5,000 for entry-level hobbyist machines to USD 150,000 for a machine decked with powerful features and functions, you have great variability to choose from. Plus, you will also have to bear the cost of installation, training, warranty, maintenance, and software.

Concluding Thoughts

A CNC Router machine can be rather expensive. And the stakes are high, considering that your choice of a CNC router machine for woodworking determines the success of your project. Use the pointers shared above to educate yourself on your primary requirements. Beyond that, all that remains is scouring the market for options and reaching a well-rounded and informed decision on the woodworking CNC machine of your choice!

About the Author:

Peter Jacobs is the Senior Director of Marketing at CNC Masters. He is actively involved in manufacturing processes and regularly contributes his insights for various blogs in CNC machining, 3D printing, rapid tooling, injection molding, metal casting, and manufacturing in general.